Value creation and new opportunities

The VOM project responds to the need for a sustainable, low-emission transition in Norway’s food system by exploring both what changes are possible and how they can be enabled. Although the food system’s impacts on emissions and land use differ across regions and nationally, there is broad agreement that transforming how food is produced, accessed, valued, and consumed is crucial to meeting the Sustainable Development Goals (SDGs) and to addressing climate change. One pathway forward is to redirect demand, innovation, and value creation toward greater production and consumption of vegetables and food grains.

Last ned som PDF

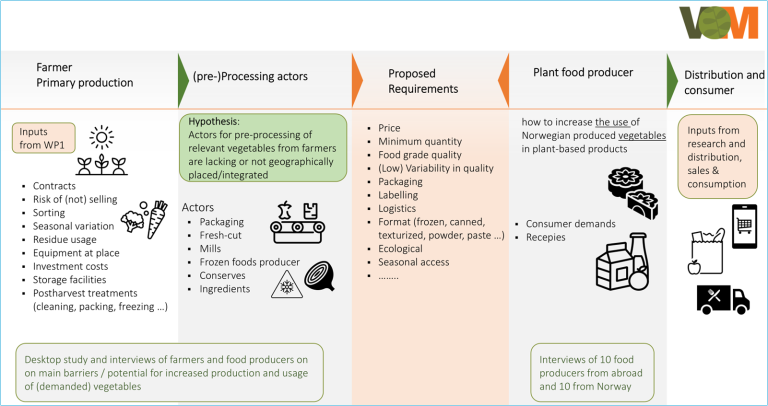

This brief summarizes the current state of the Norwegian vegetable supply chain, focusing on vegetables used or potentially used in plant-based foods and ingredients. The research highlights challenges and opportunities for increasing fresh consumption and integrating Norwegian vegetables into processed plant-based products. Furthermore, the research explores the dynamics and barriers across the value chain, particularly within pre-processing.

In addition, we analyzed the role that taste plays in ensuring consumer acceptance of plant-based products and how current Norwegian products perform.

The main results of VOM are presented in the report “Norwegian Vegetables for Plant-Based Food - Understanding Challenges and Opportunities in the Vegetable Value Chain” . Here, we highlight the main findings, which lead to recommendations.

Figure 1 illustrates the structure of the vegetable value chain in Norway, which is essential for pinpointing both the opportunities and the obstacles to innovating plant-based products (Fig. 1). One critical aspect is that plant-based food production—whether by small, medium, or large companies—relies on tailored pre-processing of raw materials adapted to the vegetable type and intended product, which happens to constitute one of the most significant obstacles, as will be explained below.

Moreover, Norway's fruit and vegetable market differs markedly from other agricultural sectors. First, there is no formal regulator, but rather other actors handle market balance under a legal exemption allowing producers to collaborate on prices and volumes. Second, target prices, set annually through agricultural agreements, guide what farmers should earn in a balanced market. Third, tariff protections shield domestic growers from foreign competition, enabling higher seasonal prices and supporting rural economies, though import options remain viable for wholesalers and industry. Finally, a significant share of vegetables and potatoes is produced under contracts for processing, giving farmers predictability.

Challenges and opportunities in Norway’s vegetable and plant-based food value chain

1. Primary production

Challenges:

- Seasonal and inconsistent yields make securing stable, high-quality volumes difficult.

- Higher domestic prices encourage imports.

- Difficulties in yield prediction hinder contractual reliability.

Opportunities:

- Expand cultivation for food (peas, faba beans, etc.) and shift focus from feed.

- Introduce climate-suitable varieties and greenhouse production to extend seasons.

- Strengthen producer–processor communication and power balance to align supply with industry needs.

2. Pre-processing & production

Challenges:

- Competition for crops between feed (e.g., salmon industry) and food uses.

- Limited and fragmented pre-processing prevents food producers from sourcing Norwegian vegetables in the proper form, quality, volume, and time, pushing them to import.

- High investment risk for new equipment/technology due to small and volatile market.

- Need for ongoing evaluation of better raw materials and new suppliers, which is labor-intensive and often unnoticed by customers.

Opportunities:

- Develop Norwegian pre-processing hubs via vertical integration, shared investments, or producer expansion.

- Strengthen farmer–producer industrial links to scale volumes and profitability.

- Focus R&D on taste and texture improvements to boost consumer acceptance.

3. Food manufacturing

Challenges:

- Difficulty adapting new products to existing production lines.

- Need continuous evaluation of raw materials and suppliers, which is resource intensive.

- Sensory gaps (taste, texture) compared to animal-based products; maintaining quality throughout shelf life.

- Shelf-life constraints for chilled/non-heat-treated plant-based products.

Opportunities:

- Build volumes to reduce waste and processing costs.

- Improve shelf-life forecasting and preservation knowledge to cut losses.

- Develop convenient and appealing formats to drive demand.

4. Retail & food service

Challenges:

- Small players struggle to access shelf space dominated by larger brands.

- Shelf-life demands and logistics challenges for fresh/chilled products.

Opportunities:

- Promote Norwegian origin with clear labelling (e.g., Nyt Norge).

- Showcase plant-based products as the default option; highlight quality and competitive pricing.

- Facilitate direct supply of less processed local raw materials to restaurant chains.

5. Consumers & market

Challenges:

- Negative perceptions of plant-based foods as ultra-processed; skepticism due to poor prior experiences.

- Habits and preferences (especially meat dominance) outweigh sustainability intentions.

- Generational differences; older consumers harder to influence.

- Rapidly shifting demands create innovation pressure; low awareness of how to use legumes and vegetables.

Opportunities:

- Educate consumers on the preparation and benefits of Norwegian vegetables and legumes.

- Highlight local origin and vegetable content in communication (without over-emphasizing “vegetarian”).

- Develop convenient, tasty products aligned with consumer habits.

- Targeted messaging for different demographic segments; leverage preference for domestic ingredients.

6. Policy & regulation

Challenges:

- Low customs duties on plant-based imports; uneven subsidy structures favoring meat.

- Lack of specific support schemes for plant-based food innovation and infrastructure.

Opportunities:

- Adjust tariffs and subsidies to level the playing field between plant-based and animal-based sectors.

- Reduce VAT on healthy, Norwegian plant-based foods.

- Provide incentives and support schemes for pre-processing, storage, and manufacturing capacity.

- Facilitate start-ups to scale production and build volumes.

Koblinger til andre ledd i verdikjeden

Upstream (farm inputs & production):

Variety choice (climate-suitable cultivars), protected/greenhouse production, harvest & storage tech directly affect year-round ingredient supply. Contracting and risk-sharing mechanisms influence growers’ willingness to expand food-grade production (vs. feed).

Midstream (pre-processing & logistics):

Location and ownership of blanching/freezing/drying/puréeing capacity determine feasibility of Norwegian sourcing for industry; shared hubs or vertical integration reduce transport and waste.

Downstream (manufacturers, retail, foodservice):

Shelf-life, chilled chains, and SKU turnover shape costs and waste; category placement, origin labelling (e.g., “Nyt Norge”), and private label partnerships shape visibility and volumes.

Consumers & culture:

Acceptance hinges on taste, simplicity, and familiar formats; education on use of legumes/veg and reframing away from “ultra-processed” perceptions are pivotal.

Policy & governance:

Target prices, tariff protection, VAT, subsidies, innovation grants, and data/monitoring (currently sparse) set the incentive landscape; alignment across agriculture, health, and industry policy is needed to lift Norwegian vegetable share.

Recommendations

1) Producer organizations & cooperatives

Aggregate and program volumes. Build multi-year crop programs with cultivar guidance and quality specs for industry use; coordinate surplus channels to nearby hubs.

Own or co-own processing links. Evaluate joint ventures with manufacturers for blanch/freeze/dry lines located near growing areas to reduce freight and losses.

2) Farmers (primary producers)

Grow for food-grade markets. Prioritize cultivars and practices suited to processing specs; explore greenhouse/season extension where viable.

Share risk and value. Use contracts with grade-flex bands (A/B quality) and pre-agreed routing of seconds to ingredients; participate in cluster investments or mobile pre-processing solutions.

3) Ingredient/pre-processing companies

Flexible, modular capacity. Invest in lines that can switch between cut/frozen/purée/dried formats to serve diverse manufacturers year-round, design for seconds and gluts.

Quality systems for shelf-life. Build know-how on texture/flavor stability over time and on interactions in mixed veg/legume matrices; offer spec sheets and predictable lead times to SMEs.

4) Food & beverage manufacturers (large brands & SMEs)

Taste first, simple labels. Prioritize flavor and convenient formats over meat mimicry; use Norwegian peas/faba beans/roots/cabbage in familiar dishes and ready components.

Portfolio & brand strategy. Consolidate best-sellers for scale (incl. private label opportunities), while signaling origin and vegetable content clearly.

Dual sourcing with local anchor. Structure supply so a domestic ingredient share is guaranteed, with imported backup to manage risk; transparently communicate the origin story.

5) Retailers & food service operators

Make vegetables the default. Improve placement, menu prominence, and origin labelling (e.g., “Nyt Norge”) for processed vegetable products; support trials with volume commitments.

Shrink waste, extend life. Collaborate on pack sizes, MMD dating, and cold-chain discipline; share sell-through data with suppliers to refine forecasting.

Consumer guidance. Provide simple in-store preparation cues/on-pack to overcome legumes/vegetables components skill gaps.

6) Civil society, nutrition & education actors

Normalize plant-rich meals. Campaigns and curricula should emphasize “veg-forward” everyday dishes and how-to skills (soaking, cooking, seasoning) to counter poor first experiences.

7) Policymakers & agencies (agriculture, industry, health)

Backbone investment in pre-processing. Co-finance regional vegetable pre-processing hubs (freezing, drying, puréeing, cutting) with open-access or multi-owner models; support upgrades for storage/cooling to valorize seconds/overruns.

Level the playing field. Review customs duty/VAT and subsidy schemes so plant-rich, health-promoting products don’t face structural disadvantages versus animal-based or imported ingredients. Pilot reduced VAT for qualifying plant-based foods with Norwegian veg content.

De-risk primary production. Expand contracts/insurance and seasonal bridging tools for climate-suitable vegetables and legumes (peas, faba beans, roots, brassicas).

Public procurement pull. Set minimum veg/legume portions and Norwegian-origin targets (where feasible) in public meals; value climate/health co-benefits in tenders.

Data & monitoring. Fund consolidated statistics on processed vegetables flows, domestic share, losses, and shelf-life waste to guide policy and industry decisions.